ISO/DIS 19713-1

(Main)Road vehicles -- Inlet air cleaning equipment for internal combustion engines and compressors

Road vehicles -- Inlet air cleaning equipment for internal combustion engines and compressors

Véhicules routiers -- Équipement d'épuration d'air d'entrée pour moteurs à combustion interne et compresseurs

General Information

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 19713-1

ISO/TC 22/SC 7 Secretariat: DIN

Voting begins on: Voting terminates on:

2008-08-04 2009-01-04

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Road vehicles — Inlet air cleaning equipment for internalcombustion engines and compressors —

Part 1:

Fractional efficiency testing with fine particles (0,3µm to 5µm

optical diameter)

Véhicules routiers — Équipement d'épuration d'air d'entrée pour moteurs à combustion interne et

compresseurs —Partie 1: Contrôle d'efficacité fractionnelle avec particules fines (diamètre optique de 0,3 µm à 5 µm)

ICS 43.060.20In accordance with the provisions of Council Resolution 15/1993 this document is circulated in

the English language only.Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est distribué

en version anglaise seulement.To expedite distribution, this document is circulated as received from the committee secretariat.

ISO Central Secretariat work of editing and text composition will be undertaken at publication

stage.Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.RECIPIENTS OF THIS DRAFT ARE INVITED TO SUBMIT, WITH THEIR COMMENTS, NOTIFICATION OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPORTING DOCUMENTATION.International Organization for Standardization, 2008

---------------------- Page: 1 ----------------------

ISO/DIS 19713-1

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright noticeThis ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user's country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, photocopying,

recording or otherwise, without prior written permission being secured.Requests for permission to reproduce should be addressed to either ISO at the address below or ISO's

member body in the country of the requester.ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii ISO 2008 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 19713-1

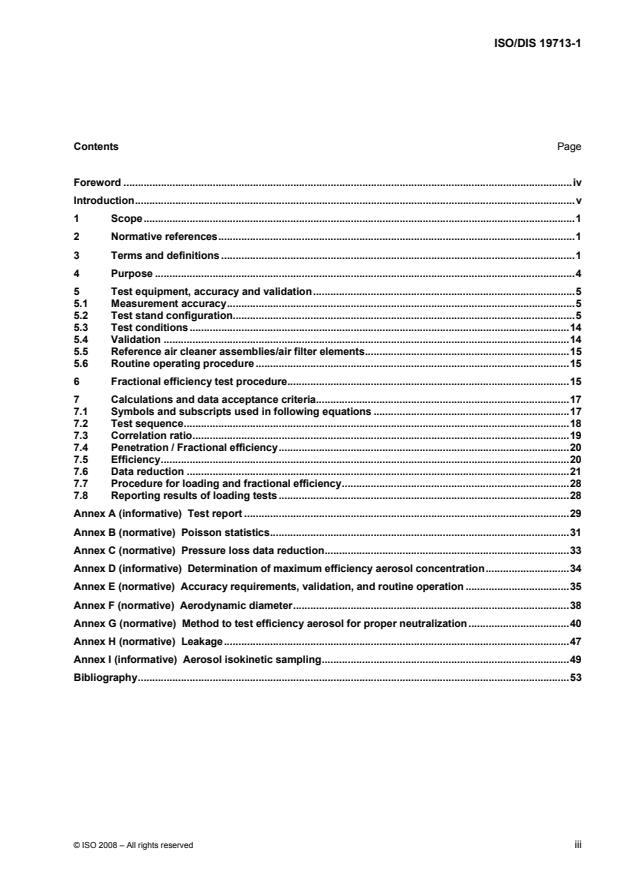

Contents Page

Foreword ............................................................................................................................................................iv

Introduction.........................................................................................................................................................v

1 Scope......................................................................................................................................................1

2 Normative references............................................................................................................................1

3 Terms and definitions ...........................................................................................................................1

4 Purpose ..................................................................................................................................................4

5 Test equipment, accuracy and validation...........................................................................................5

5.1 Measurement accuracy.........................................................................................................................5

5.2 Test stand configuration.......................................................................................................................5

5.3 Test conditions ....................................................................................................................................14

5.4 Validation .............................................................................................................................................14

5.5 Reference air cleaner assemblies/air filter elements.......................................................................15

5.6 Routine operating procedure .............................................................................................................15

6 Fractional efficiency test procedure..................................................................................................15

7 Calculations and data acceptance criteria........................................................................................17

7.1 Symbols and subscripts used in following equations ....................................................................17

7.2 Test sequence......................................................................................................................................18

7.3 Correlation ratio...................................................................................................................................19

7.4 Penetration / Fractional efficiency.....................................................................................................20

7.5 Efficiency..............................................................................................................................................20

7.6 Data reduction .....................................................................................................................................21

7.7 Procedure for loading and fractional efficiency...............................................................................28

7.8 Reporting results of loading tests.....................................................................................................28

Annex A (informative) Test report .................................................................................................................29

Annex B (normative) Poisson statistics........................................................................................................31

Annex C (normative) Pressure loss data reduction.....................................................................................33

Annex D (informative) Determination of maximum efficiency aerosol concentration.............................34

Annex E (normative) Accuracy requirements, validation, and routine operation ....................................35

Annex F (normative) Aerodynamic diameter................................................................................................38

Annex G (normative) Method to test efficiency aerosol for proper neutralization...................................40

Annex H (normative) Leakage........................................................................................................................47

Annex I (informative) Aerosol isokinetic sampling......................................................................................49

Bibliography......................................................................................................................................................53

© ISO 2008 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 19713-1

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 19713-1 was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 7, Injection

equipment and filters for use on road vehicles.ISO 19713 consists of the following parts, under the general title Road vehicles — Inlet air cleaning equipment

for internal combustion engines and compressors:⎯ Part 1: Fractional efficiency testing with fine particles (0,3 μm to 5 μm optical diameter)

⎯ Part 2: Fractional efficiency testing with coarse particles (5 μm to 40 μm optical diameter)

iv © ISO 2008 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 19713-1

Introduction

The following Engine Air Cleaner/Filter Fractional Efficiency Test Standard has been developed to cover

traditional and new particulate air filters to remove airborne contaminants specifically to protect the engine.

Air Cleaner Fractional Efficiency is one of the main air cleaner performance characteristics. This Test

Standard has been established to address the measurement of this parameter. The objective of this

procedure is to maintain a uniform test method for evaluating fractional efficiency of air cleaners and air filters

on specified laboratory test stands.The data collected according to this test standard can be used to establish fractional efficiency characteristic

for air cleaners and filters tested in this manner. The actual field operating conditions, including contaminants,

humidity, temperature, mechanical vibration, flow pulsation, etc. are difficult to duplicate. However, with the

procedure and equipment set forth, comparison of air filter fractional efficiency may be made with a high

degree of confidence.Annexes, B, C, E, F, G, and H are normative. Annexes A, D, and I are informative.

© ISO 2008 – All rights reserved v---------------------- Page: 5 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 19713-1

Road vehicles — Inlet air cleaning equipment for internal

combustion engines and compressors —

Part 1:

Fractional efficiency testing with fine particles (0,3µm to 5µm

optical diameter)

1 Scope

This part of ISO 19713 describes laboratory test methods to measure engine air cleaner and filter

performance by fractional efficiency test using particles from 0,3 µm to 5 µm. See ISO 19713-2 for fractional

efficiency test with particles from 5 µm to 40 µm. Performance includes, but is not limited to, air flow restriction

or pressure loss, initial and incremental fractional efficiencies during dust loading.

2 Normative referencesThe following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) appliesISO 19713-2, Inlet air cleaning equipment for internal combustion engines and compressors — Part 2:

Fractional efficiency testing with coarse particles (5 to 40 µm optical diameter)

ISO 5011:2000, Inlet air cleaning equipment for internal combustion engines and compressors - performance

testingISO/DP 11 841-1, Road vehicles and internal combustion engines - Filter vocabulary - Part 1: Definitions of

filters and filter componentsISO 12103-1, Road vehicles – Test dust for filter evaluation – Part 1: Arizona test dust

ISO/TS 11155-1, Road vehicles - Air filters for passenger compartment - Part 1: Test for particulate filtration

ASTM F 328, Practice for determining counting and sizing accuracy of an airborne particle counter using near-

mono-dispersed spherical particulate materials, (ASTM, 1916 Race Street, Philadelphia, PA. 19103-1187

USA)ASHRAE 52.2, Method of testing general ventilation air-cleaning devices for removal efficiency by particulate

size (ASHRAE, 1791 Tullie Circle, N.E., Atlanta, GA. 30329, USA)3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

air cleaner assembly

assembly which includes the air cleaner housing and the air filter element

© ISO 2008 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/DIS 19713-1

3.1.1

single stage air cleaner

air cleaner which does not incorporate a separate pre-cleaner

3.1.2

multistage air cleaner

air cleaner consisting of two or more stages, the first usually being a pre-cleaner, followed by one or more

filter elementsNOTE If two elements are used, the first is called the primary element and the second one is called the secondary

element.3.1.3

pre-cleaner

device usually using inertial or centrifugal means to remove a portion of the test dust before reaching the filter

element3.2

air filter element

the actual filter supported and sealed within the air cleaner assembly

3.3

test air flow rates

a measure of the volume of air passing through the test duct per unit time

NOTE Expressed in cubic meters per second (m³/s).

3.4

pressure loss

permanent pressure reduction due to a decrease in the flow energy (velocity head) caused by the filter (Pa at

standard conditions of 20 ºC and 101,3 kPa)3.5

term fractional efficiency, E (%)

f,i

ability of the air filter to remove particles of a specified size expressed as a percentage for particle size i

C C1i 2i

= ×100 (1)

E f ,i

where: C = number of particles per unit volume of specified size, i upstream

C = number of particles per unit volume of specified size, i downstream

3.6

definition of different fractional efficiencies

3.6.1

fractional efficiency before dust loading

efficiency before the collected particles have any measurable effect on the efficiency of the filter under test

NOTE The collected particles can affect the measured filter efficiency before enough aerosol is collected to have any

measurable effect on the filter pressure loss.3.6.2

incremental fractional efficiency

efficiency, determined at the specified flow rate as a function of particle size at 10 %, 25 %, 50 % and 100 %

of filter life, which is determined by pressure loss across the filter as the filter is loaded with ISO 12103-1 test

dust.2 © ISO 2008 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/DIS 19713-1

NOTE 1 The filter pressure loss (ΔP) values at which the incremental fractional efficiencies are measured can be

calculated from: the initial pressure loss (ΔP ), the fraction of filter life (ΔL), and the specified terminal pressure loss (ΔP ).

o i dSee Equation 2.

ΔP=ΔP+ΔL× (ΔP −ΔP )

i o i d o

(2)

NOTE 2 If necessary, the requester and the tester may agree upon different criteria for incremental fractional efficiency.

3.7fractional penetration, P (%)

f,i

ratio of the concentration of particles of specified size exiting the filter to the concentration of particles of

specified size entering the filter expressed in a percentage for particle size i(3)

= 100− E

f ,i

f ,i

3.8

test dust loading

mass of test dust collected by the air cleaner assembly or air filter element at a specified flow rate expressed

in grams3.9

particle measurement device / aerosol spectrometer

instrument for sizing and/or counting aerosol particles

NOTE Recommended particle counters are optical particle counters (OPC) or other counters demonstrating good

correlation in measuring particle sizes such as aerodynamic particle counters (APC).

3.10test aerosol

particles suspended in air, used for filter efficiency evaluation or dust loading

3.10.1fractional efficiency test aerosol

aerosol used to measure the efficiency of the test filter, the concentration of which is low enough to prevent

coincidence related errors in the particle counters, and does not change the filter efficiency due to loading; for

this part of ISO 19713, the KCl (potassium chloride) test aerosol shall be usedNOTE The aerosol charge is reduced so that it approximates a Boltzman equilibrium charge distribution. The

requirements for the efficiency challenge aerosol are given in sections 5.2.9 and 5.2.10.

3.10.2loading test aerosol

aerosol used to load the filter, the concentration of which is high enough to allow loading of the filter in a

reasonable amount of time; for this part of ISO 19713 for single-stage air cleaner assemblies and air filter

elements, ISO 12103-1 A2 test dust and for pre-cleaners and multistage air cleaner assemblies ISO 12103-1

A4 test dust shall be usedNOTE The requirements for the loading test aerosol are given in section 5.2.12.1.

3.11correlation ratio, R

ratio of the number of particles observed at the downstream sampling location to the number of particles at the

upstream sampling location when no filter is installed in the test systemNOTE 1 This number may be greater or less than 1.

NOTE 2 The method of calculating the correlation ratio is given in Annex B.

© ISO 2008 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/DIS 19713-1

3.12

Log mean diameter, D

l,i

weighted mean diameter calculated by

1/ 2

D =()D× D (4)

li i i

where

D = log mean diameter

l,i

D = lower threshold of particle size range

D = upper threshold of particle size range

i+1

3.13

geometric (volume equivalent) diameter, D

g,i

diameter of a sphere with the same volume as the particle being measured

NOTE For a spherical particle, it is the diameter of the sphere.

3.14

optical (equivalent) diameter, D

o,i

diameter of a particle of the type used to calibrate an optical sizing instrument that scatters the same amount

of light as the particle being measuredNOTE Optical diameter depends on the instrument, the type of particle used to calibrate the instrument (usually

polystyrene latex spheres), the optical properties of the particle being measured, and the size of the particle.

3.15aerodynamic (equivalent) diameter, D

diameter of a sphere of density 1 g/cm with the same terminal velocity due to gravitational force in calm air,

as the particle being measuredNOTE 1 The aerodynamic diameter will be used to report results to avoid different diameter measures due to different

sizing and counting techniques.NOTE 2 Annex F provides additional information about aerodynamic diameter.

3.16

High Efficiency Particulate Air

HEPA

for this part of ISO 19713, HEPA is defined as a filter having 99,95 % efficiency at most penetrating particle

size (class H13 according to EN 1822) or 99,97 % (or higher) fractional efficiency at 0,3 µm using DOP

aerosol as defined by IEST RPCC001 recommended practice3.17

neutralization

aerosol whose charge distribution is reduced until it provides a Boltzman equilibrium charge distribution

4 PurposeThe purpose of this test code is to establish and specify consistent test procedures, conditions, equipment,

and performance reports to enable comparison of filter performances of air cleaners and air filter elements

used in engine air induction systems. It specifies the critical characteristics of equipment, test procedure and

report format required for the consistent assessment of filter elements in a laboratory test stand with particle

sizes in the range of 0,3 µm to 5 µm (optical diameter). The test procedure enables an assessment of air

cleaners for pressure loss and fractional efficiency against standardized laboratory particulate challenges.

Because the test methods exclude the full range of possible particulate challenges and environmental effects,

the relative ranking of filters may change in service. Note that absolute comparability is only possible with air

cleaners the same shape and size as well as the same position in the test duct. In order to get comparable

4 © ISO 2008 – All rights reserved---------------------- Page: 9 ----------------------

ISO/DIS 19713-1

results to the dust loading capacity, gravimetric efficiency and air flow restriction/pressure loss tests, the

fractional efficiency test can be done simultaneously. (Refer to ISO 5011).5 Test equipment, accuracy and validation

5.1 Measurement accuracy

Accuracy requirements are given in Annex E, Table E.1

5.2 Test stand configuration

Complete vehicle manufacturers air cleaner assemblies or individual air filter elements may be tested. The

test stand shall consist of the following major components and shall be arranged as shown in Figure 2.

NOTE 1 Depending on configuration results may vary.NOTE 2 Air cleaner assembly orientation will affect performance. It is recommended that air cleaner assemblies will be

oriented and tested as installed in the vehicle.Figure 2 shows a set up to measure the performance of an air cleaner assembly.

Figure 3 shows a recommended air cleaner housing to measure the performance of a panel type air filter

element.Figure 4 shows a recommended air cleaner housing to measure the performance of a cylindrical type air filter

element.5.2.1 Unit under test

The unit under test may be an air cleaner housing with filter element or elements or it may be a housing

designed to hold a filter element with appropriate inlet and outlets. The unit under test may be or may include

a pre-cleaner. The scope of this test procedure does not include the testing of air cleaner systems without

tubular inlet and outlet connections. However designs such as perforated or louvered inlet systems could be

tested with the unit under test inside a plenum that would include a tubular inlet. Non-tubular air cleaner

systems outside the scope of this test procedure may still be evaluated as agreed upon between the tester

and customer.5.2.1.1 Air cleaner assembly

Air cleaner assemblies will be evaluated using the set up shown in Figure 2.

5.2.1.2 Evaluating panel air filter elements

In general, panel type air filter elements may be tested using the recommended housing shown in Figure 3.

5.2.1.3 Evaluating cylindrical/round air filter elementsFigure 4 shows a recommended housing to test cylindrical type air filter elements. This housing design is

similar to the one recommended in ISO 5011.5.2.2 Ducting

Upstream and downstream cylindrical ducting shall be made of conductive material and all components shall

be commonly grounded from the aerosol inlet section to the downstream sampling section.

© ISO 2008 – All rights reserved 5---------------------- Page: 10 ----------------------

ISO/DIS 19713-1

5.2.3 Air flow conditioning

Inlet air shall be conditioned according to the requirements of ISO 5011, (23 ± 5 °C and 55 ± 15% RH). The

inlet air shall be filtered with a HEPA filter if the background particle concentration exceeds the requirements

in 7.6.2.3 and 7.6.4.3.5.2.4 Test configurations

The upstream and downstream ducting can be constructed vertically (recommended), horizontally or a

combination based on space constraints. The example in this procedure shows a vertical configuration to test

both air cleaners and panel type air filters. The particle samplers are located vertically in each test section,

which reduces the probability of particle loss and enable sampling of large particle sizes of interest. The

underlying test system design will reduce particle losses and meet the requirements of Table E.1 and E.2 in

Annex E.5.2.5 Air flow ducting

The test system should be capable of handling user specified flow rates. Further, the test system will maintain

the required flow rates with air cleaner assembly pressure loss up to 10 kPa. Primary duct sizing shall conform

to the following 'nominal' duct diameter and flow ranges in Table 1 below. Higher and lower flow rates may

use duct sizes scaled appropriately.Table 1 — Duct diameter vs. flow range

Nominal

Flow range Flow range

duct Area Velocity Reynolds number

low high

diameter

2 3 3

mm m m/s m/hr m /hr at low flow at high flow

50 0,00202 11,6 85 425 40407 202034

100 0,0081 170 850 40407 202034

5,8

150 0,0182 5,2 340 1700 53876 269378

200 0,0324 5,8 680 3400 80813 404067

NOTE A 10 µm particle with a specific gravity of 2 settles at about 6 x10 m/s in still air. At the minimum velocity of

approximately 5,1 m/s this would result in only a 10 mm drop in that 10 µm particle over a 3 m run.

5.2.6 Inlet filtrationTest inlet air flow shall be filtered with a HEPA filter to remove the majority of ambient aerosol if required

according to Annex E.5.2.7 Flow uniformity

The test system shall be designed to provide uniform and steady air flow to the air cleaner assembly or to the

air filter element under test as stated in the test set up.NOTE Uniform air flow is required in sections where isokinetic samplers are located when evaluating air cleaner

assemblies. Proper flow distribution will facilitate a representative aerosol sample being drawn by the isokinetic samplers.

Refer to 5.2.9.3 for flow uniformity measurements.6 © ISO 2008 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/DIS 19713-1

5.2.8 Leakage

It is important to minimize leakage into the test system to obtain good data. Depending on where the leakage

occurs, it can cause major errors in particle counting.As a minimum all connections and joints should be checked for visual leakage using soap bubbles. Any

known soap solution can be used for the test. Preferably, the soap solution [foam] will be applied using a

brush at all connections and joints. Leaks are especially important on the clean side of the air cleaner. See

Annex H for more information.5.2.9 Fractional efficiency test aerosol generator

The aerosol generator for fractional efficiency tests shall provide a stable and homogenous aerosol

concentration and size distribution. The size distribution of the aerosol shall have sufficient particles for

statistical evaluation in each size class as explained in Section 7. If high-resolution particle spectrometers are

used, size classes may be combined to achieve the required counts using the size ranges in 5.2.13. The total

concentration of the aerosol in the test duct shall not exceed the limit of the particle counter as discussed in

5.2.13.3. The efficiency test aerosol concentration shall be low enough so there is no change in efficiency

during the test as measured by the penetration data acceptance criteria in 7.6.4 (i.e. no loading effects). The

size distribution and concentration stability requirements are established by the data quality requirements in

clause 7.5.2.9.1 Aerosol generation

The potassium chloride aerosol generator for fractional efficiency tests shall nebulize a saline solution to

produce a homogeneous mist aerosol with stable concentration and size distribution. The droplets shall be

dried to form salt particles by using e.g. dry dilution air, heat, or desiccant. The efficiency test aerosol

generator shall be capable of dispersing KCl (potassium chloride aerosol) at a concentration low enough to

meet coincidence error requirements for the particle counter used. Compressed air used to operate and

transport the challenge aerosol should be HEPA filtered and dried before entering the feeding system.

5.2.9.2 Aerosol dispersionThe efficiency test aerosol should be injected against the air flow coming from the inlet HEPA filter(s). Care

should be taken to keep the injection velocity low enough to keep the larger particles in the challenge aerosol

from impacting on the walls of the inlet aerosol ductwork. The objective is to allow the inlet air to turn the

challenge aerosol and result in a more uniform distribution of concentration and particles size distribution

across the duct even before it enters the upstream static mixer.5.2.9.3 Aerosol uniformity

During validation of uniformity and concentration of the efficiency test aerosol, no

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.